Sawing and cut-off units, integrated into complete finishing lines

Aktualisiert am: 21.07.2009 10:39

Sawing and cut-off units, manufactured by sema Systemtechnik Sewing GmbH & Co.KG, Hüllhorst (Germany), are mostly built up as complete lines and designed as panel cutters. Herewith material length of up to 24 m can be sawed according to customers requirements to length between 2 24 m.

The panel cutters consist of two or more sawing aggregates, which are automatical and motorical moveable in longitudinal axis of the material length to be cut. The input of the required length is done at the operating panel. The length accuracy of the sawed sections is +/- 1 mm.

For cutting tubes the saws are equipped with sawing optimization: During the cut of the stud the sawing feed occurs more quickly. The optimised feed and cutting speed can be saved after setting up as a program in the machine control and are reproduceable at any time.

With this integrated sawing and cut-off combinations it is possible to produce by using three saws in one axis and one offset saw 1 to 3 fixed lengths or 1 to 2 fixed lengths and one production length.

The materials are lined up axially and handed over by using carrier arms into the sawing area. The cut material sections are taken again by carrier arms and laid down on the subsequent station, which can be a brush-de-burring or a chamfering machine. By using this saws it is not only possible to cut one tube or bar, also two tubes/bars can be processed simultaneously.

The sawing aggregates are built up above a central chip conveyor. Chips and residual pieces fall onto this conveyor and are transported out of the machine.

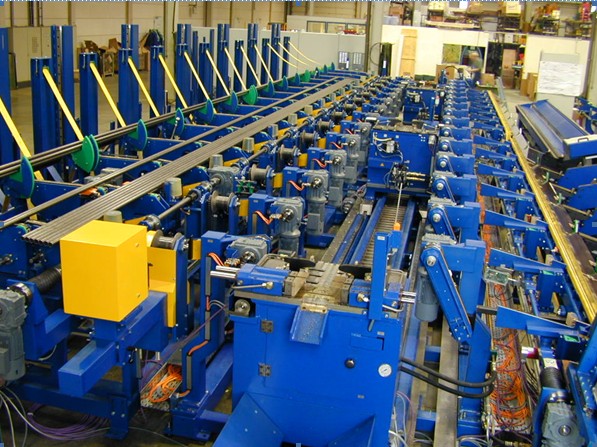

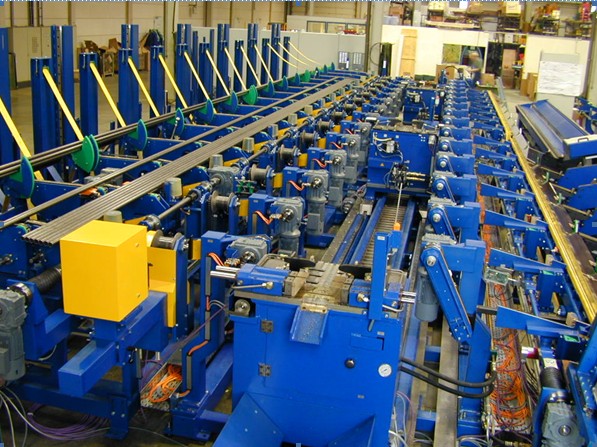

The shown line configuration contains a pre-storage for tube bundles, the separating unit as well as a line of robotic carrier arms for placing the tubes into the sawing area. The main item is the sawing section with three sawing aggregates and the chip conveyor. A further line of carrier arms is used for taking of the tubes out of the sawing section. An allocation to the axial transport of the individual tube sections with transfer to the de-burring station as well as a collecting trough round off the entire system.

These sawing and cut-off combinations for producing tube fixed and production length contain the necessary peripheral equipment for handling the incoming materials as well as the cut tube sections.

From our viewpoint the trend goes along, that during production of tubes and bars machines are linked increasingly more strongly and that the sawing and cut-off systems are an important component of this production lines. These linkages have the advantage that the transports inside a factory as well as waiting times of the crane are minimized and the productivity is increased significantly.

Possible linkages of sawing lines:

Straightening Sawing - Packaging

Straightening Sawing End processing - Packaging

Straightening Testing Sawing End processing - Packaging

or according to customers requirements

For more information please visit our website:

www.sema-systemtechnik.de

sema Systemtechnik GmbH

Bredenhop 27

32609 Hüllhorst

Telefon: +49 (0) 5744 / 9318-0

Telefax: +49 (0) 5744 / 9318-91

e-Mail: info@sema-systemtechnik.de

The panel cutters consist of two or more sawing aggregates, which are automatical and motorical moveable in longitudinal axis of the material length to be cut. The input of the required length is done at the operating panel. The length accuracy of the sawed sections is +/- 1 mm.

For cutting tubes the saws are equipped with sawing optimization: During the cut of the stud the sawing feed occurs more quickly. The optimised feed and cutting speed can be saved after setting up as a program in the machine control and are reproduceable at any time.

With this integrated sawing and cut-off combinations it is possible to produce by using three saws in one axis and one offset saw 1 to 3 fixed lengths or 1 to 2 fixed lengths and one production length.

The materials are lined up axially and handed over by using carrier arms into the sawing area. The cut material sections are taken again by carrier arms and laid down on the subsequent station, which can be a brush-de-burring or a chamfering machine. By using this saws it is not only possible to cut one tube or bar, also two tubes/bars can be processed simultaneously.

The sawing aggregates are built up above a central chip conveyor. Chips and residual pieces fall onto this conveyor and are transported out of the machine.

The shown line configuration contains a pre-storage for tube bundles, the separating unit as well as a line of robotic carrier arms for placing the tubes into the sawing area. The main item is the sawing section with three sawing aggregates and the chip conveyor. A further line of carrier arms is used for taking of the tubes out of the sawing section. An allocation to the axial transport of the individual tube sections with transfer to the de-burring station as well as a collecting trough round off the entire system.

These sawing and cut-off combinations for producing tube fixed and production length contain the necessary peripheral equipment for handling the incoming materials as well as the cut tube sections.

From our viewpoint the trend goes along, that during production of tubes and bars machines are linked increasingly more strongly and that the sawing and cut-off systems are an important component of this production lines. These linkages have the advantage that the transports inside a factory as well as waiting times of the crane are minimized and the productivity is increased significantly.

Possible linkages of sawing lines:

Straightening Sawing - Packaging

Straightening Sawing End processing - Packaging

Straightening Testing Sawing End processing - Packaging

or according to customers requirements

For more information please visit our website:

www.sema-systemtechnik.de

sema Systemtechnik GmbH

Bredenhop 27

32609 Hüllhorst

Telefon: +49 (0) 5744 / 9318-0

Telefax: +49 (0) 5744 / 9318-91

e-Mail: info@sema-systemtechnik.de