RSA on Aluminium exhibition in Essen

Aktualisiert am: 14.08.2006 09:35

Trend towards complex aluminium extrusions:

Efficient and universal deburring systems at the

Aluminium exhibition in Essen

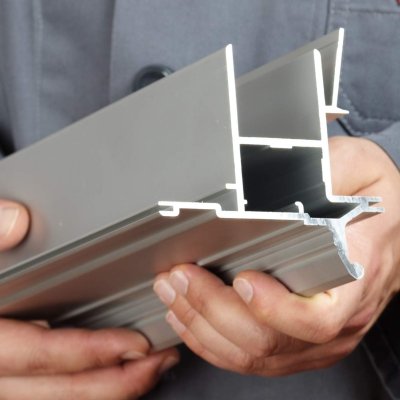

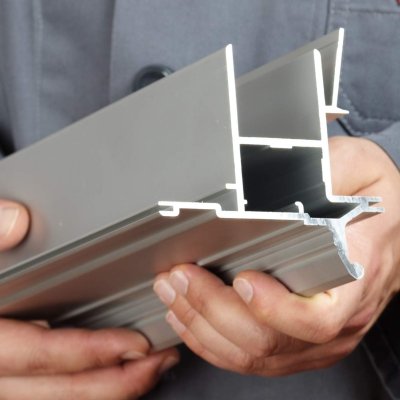

The endeavours of the car designers to go on improving the consumption and performance values of cars by reducing weight, keep the use of aluminium in the focus of technical development. In this connection a trend towards more complex geometries becomes evident. In particular, when steel workpieces are replaced by aluminium extrusions, static and safety-related aspects lead to an ever increasing complex design of extrusions resulting in high demands on production and further processing.

The endeavours of the car designers to go on improving the consumption and performance values of cars by reducing weight, keep the use of aluminium in the focus of technical development. In this connection a trend towards more complex geometries becomes evident. In particular, when steel workpieces are replaced by aluminium extrusions, static and safety-related aspects lead to an ever increasing complex design of extrusions resulting in high demands on production and further processing.

At the industrial exhibition "Aluminium 2006" which will take place in Essen from September 20th to September 22nd, 2006, many of these challenges and possible solutions will come up.

Efficient deburring systems for complex extrusion shapes

RSA Entgrat- u. Trenn-Systeme is among more than 600 expected exhibitors from more than 38 nations. It will show deburring systems being particularly developed for aluminium extrusions. The high degree of efficiency becomes evident due to the fact that one tool is sufficient for the deburring of all possible shapes. The respective machine concepts differ in the level of automation. At the exhibition, machines with manual workpiece feeding for the easy deburring of single pieces and small batches can be seen in action as well as automatic solutions operating fully automatically with the possibility of linking to other machines.

A second aspect of the efficiency is the extremely short set-up times. Especially a versatile production, small batches or the deburring of single pieces are demanding short ancillary times for resetting. As it is not necessary to change the tool, the setting of the deburring machines is restricted to the workpiece size. In case of stand-alone solutions with manual feeding this is done with only a few manual movements so that the setting-up is done within seconds. Automatic deburring machines adjust to the workpiece parameters automatically, either by entering the height and the length of the workpiece at the operating panel or by taking over the parameters from the preceding machine.

The third aspect of the high rationalisation potential is the short deburring time. Independent of the extrusion shape, all edges are properly rounded off inside and outside within a few seconds. Normally the deburring takes three seconds per end face in the case of manual feeding. Automatic machines realise cycle times from 2 up to 12 seconds for a simultaneous deburring of both end faces.

A universal tool for all kinds of extrusion geometries

For optimum deburring of all corners of an aluminium extrusion, RSA has developed a tool which is similar to a surface brush, but without the well-known disadvantages. The wire trimming of the RSA special brush which is called RASAMAT is divided into separate segments which are supported by plates. This has a significant advantage over conventional surface brushes. The wires do not bend neither through centrifugal force nor throughout the working process. Therefore it is guaranteed that the wire tips only reach the ends of the extrusions rather than touching the surfaces. The result is an ever perfect deburring result during the whole lifetime of the tool and a workpiece without any damaged surfaces. Even painted or anodized workpieces can be deburred.

For optimum deburring of all corners of an aluminium extrusion, RSA has developed a tool which is similar to a surface brush, but without the well-known disadvantages. The wire trimming of the RSA special brush which is called RASAMAT is divided into separate segments which are supported by plates. This has a significant advantage over conventional surface brushes. The wires do not bend neither through centrifugal force nor throughout the working process. Therefore it is guaranteed that the wire tips only reach the ends of the extrusions rather than touching the surfaces. The result is an ever perfect deburring result during the whole lifetime of the tool and a workpiece without any damaged surfaces. Even painted or anodized workpieces can be deburred.

At the Aluminium exhibition, hall 1, stand 1 G35, you will receive further details regarding the functioning of the systems from RSA technicians. Interested parties will have the opportunity to test the different deburring systems.

Efficient and universal deburring systems at the

Aluminium exhibition in Essen

The endeavours of the car designers to go on improving the consumption and performance values of cars by reducing weight, keep the use of aluminium in the focus of technical development. In this connection a trend towards more complex geometries becomes evident. In particular, when steel workpieces are replaced by aluminium extrusions, static and safety-related aspects lead to an ever increasing complex design of extrusions resulting in high demands on production and further processing.

The endeavours of the car designers to go on improving the consumption and performance values of cars by reducing weight, keep the use of aluminium in the focus of technical development. In this connection a trend towards more complex geometries becomes evident. In particular, when steel workpieces are replaced by aluminium extrusions, static and safety-related aspects lead to an ever increasing complex design of extrusions resulting in high demands on production and further processing.

At the industrial exhibition "Aluminium 2006" which will take place in Essen from September 20th to September 22nd, 2006, many of these challenges and possible solutions will come up.

Efficient deburring systems for complex extrusion shapes

RSA Entgrat- u. Trenn-Systeme is among more than 600 expected exhibitors from more than 38 nations. It will show deburring systems being particularly developed for aluminium extrusions. The high degree of efficiency becomes evident due to the fact that one tool is sufficient for the deburring of all possible shapes. The respective machine concepts differ in the level of automation. At the exhibition, machines with manual workpiece feeding for the easy deburring of single pieces and small batches can be seen in action as well as automatic solutions operating fully automatically with the possibility of linking to other machines.

A second aspect of the efficiency is the extremely short set-up times. Especially a versatile production, small batches or the deburring of single pieces are demanding short ancillary times for resetting. As it is not necessary to change the tool, the setting of the deburring machines is restricted to the workpiece size. In case of stand-alone solutions with manual feeding this is done with only a few manual movements so that the setting-up is done within seconds. Automatic deburring machines adjust to the workpiece parameters automatically, either by entering the height and the length of the workpiece at the operating panel or by taking over the parameters from the preceding machine.

The third aspect of the high rationalisation potential is the short deburring time. Independent of the extrusion shape, all edges are properly rounded off inside and outside within a few seconds. Normally the deburring takes three seconds per end face in the case of manual feeding. Automatic machines realise cycle times from 2 up to 12 seconds for a simultaneous deburring of both end faces.

A universal tool for all kinds of extrusion geometries

For optimum deburring of all corners of an aluminium extrusion, RSA has developed a tool which is similar to a surface brush, but without the well-known disadvantages. The wire trimming of the RSA special brush which is called RASAMAT is divided into separate segments which are supported by plates. This has a significant advantage over conventional surface brushes. The wires do not bend neither through centrifugal force nor throughout the working process. Therefore it is guaranteed that the wire tips only reach the ends of the extrusions rather than touching the surfaces. The result is an ever perfect deburring result during the whole lifetime of the tool and a workpiece without any damaged surfaces. Even painted or anodized workpieces can be deburred.

For optimum deburring of all corners of an aluminium extrusion, RSA has developed a tool which is similar to a surface brush, but without the well-known disadvantages. The wire trimming of the RSA special brush which is called RASAMAT is divided into separate segments which are supported by plates. This has a significant advantage over conventional surface brushes. The wires do not bend neither through centrifugal force nor throughout the working process. Therefore it is guaranteed that the wire tips only reach the ends of the extrusions rather than touching the surfaces. The result is an ever perfect deburring result during the whole lifetime of the tool and a workpiece without any damaged surfaces. Even painted or anodized workpieces can be deburred.

At the Aluminium exhibition, hall 1, stand 1 G35, you will receive further details regarding the functioning of the systems from RSA technicians. Interested parties will have the opportunity to test the different deburring systems.