RSA holding course at the half-year

Aktualisiert am: 04.09.2007 17:37

Volume of orders increased by 160 % in the course of the year

RSA reports that, after six months of the calendar and fiscal year 2007 have passed the company is holding course to achieve the envisaged growth in sales in double figures. The specialist in the rationalization of the pre-production revolving around the subject of sawing tubes, sections, and solid bars noticed an increase in the volume of orders of about 160 % in the course of the year.

According to business manager Dipl.-Ing. Rainer Schmidt this development is not only the result of the upward economic trend: "The reason why we are growing above the average of the branch is mainly due to our product strategy. The trend of our customers to dissociate themselves from the increasing tube imports from the Far East requires customized production concepts." RSA e.g. launched from the end of 2006 up to now four new sawing concepts - both further developed from already existing modules and even completely new developments.

According to business manager Dipl.-Ing. Rainer Schmidt this development is not only the result of the upward economic trend: "The reason why we are growing above the average of the branch is mainly due to our product strategy. The trend of our customers to dissociate themselves from the increasing tube imports from the Far East requires customized production concepts." RSA e.g. launched from the end of 2006 up to now four new sawing concepts - both further developed from already existing modules and even completely new developments.

For instance, one of the new developments concerns a saw that meets the special requirements of the steel trade and the pre-production of forged products. The use of a RASACUT XXL for the cutting of tubes of a wall thickness up to 15 mm and diameters up to 170 mm as well as solid bars of diameters up to 160 mm results in a cutting time reduction by up to 90 % compared to up-to-date band saws - while the quality of the cut surface is significantly improved.

For instance, one of the new developments concerns a saw that meets the special requirements of the steel trade and the pre-production of forged products. The use of a RASACUT XXL for the cutting of tubes of a wall thickness up to 15 mm and diameters up to 170 mm as well as solid bars of diameters up to 160 mm results in a cutting time reduction by up to 90 % compared to up-to-date band saws - while the quality of the cut surface is significantly improved.

For stainless steel processors, RSA is providing the saw RASACUT TC which is able to cut thin-walled tubes of a wall thickness from 0.4 mm without deforming them and protecting their surface.

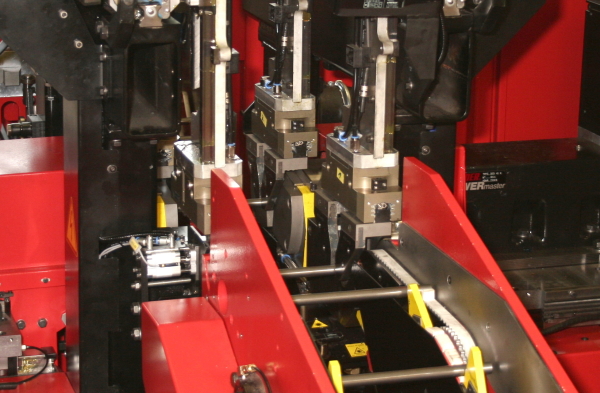

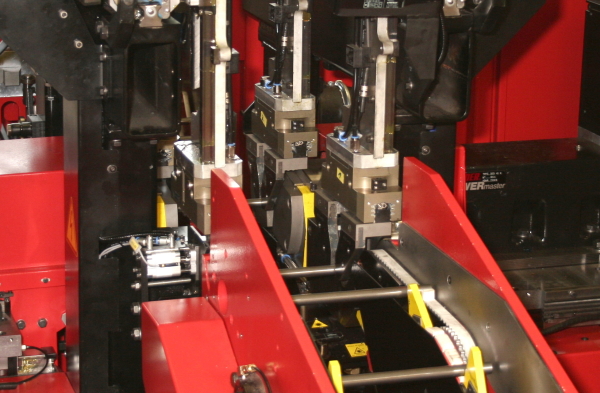

For the main customers of the components suppliers to the automotive industry, RSA developed two sawing centers for specific applications. One is designed for the production of vehicle lines from 0.6 mm diameter that are deburred or chamfered on both ends and subsequently cleaned on the inside and outside with a degree of purity never reached before.

A second specialized sawing center concerns the high precision cutting, facing, chamfering, and checking of solid bars to be further processed into motor shafts.

Though there is a good domestic demand, RSA sees a market potential for these state of the art installations more likely abroad. It is evident that the East European countries move up and do no longer use lower labour costs as an argument, but also convince with quality.

According to Rainer Schmidt, the increase in orders does not result in delivery delays: "Though our delivery times are shorter than the usual delivery times in the market, we are aiming at even significantly reduced delivery times, however, this is really impossible to realize at the moment. Otherwise we are able to meet our delivery times, because we have allowed for the growth - and as a result extended the production capacities and the resources of the after-sales service."

RSA reports that, after six months of the calendar and fiscal year 2007 have passed the company is holding course to achieve the envisaged growth in sales in double figures. The specialist in the rationalization of the pre-production revolving around the subject of sawing tubes, sections, and solid bars noticed an increase in the volume of orders of about 160 % in the course of the year.

According to business manager Dipl.-Ing. Rainer Schmidt this development is not only the result of the upward economic trend: "The reason why we are growing above the average of the branch is mainly due to our product strategy. The trend of our customers to dissociate themselves from the increasing tube imports from the Far East requires customized production concepts." RSA e.g. launched from the end of 2006 up to now four new sawing concepts - both further developed from already existing modules and even completely new developments.

According to business manager Dipl.-Ing. Rainer Schmidt this development is not only the result of the upward economic trend: "The reason why we are growing above the average of the branch is mainly due to our product strategy. The trend of our customers to dissociate themselves from the increasing tube imports from the Far East requires customized production concepts." RSA e.g. launched from the end of 2006 up to now four new sawing concepts - both further developed from already existing modules and even completely new developments.

For instance, one of the new developments concerns a saw that meets the special requirements of the steel trade and the pre-production of forged products. The use of a RASACUT XXL for the cutting of tubes of a wall thickness up to 15 mm and diameters up to 170 mm as well as solid bars of diameters up to 160 mm results in a cutting time reduction by up to 90 % compared to up-to-date band saws - while the quality of the cut surface is significantly improved.

For instance, one of the new developments concerns a saw that meets the special requirements of the steel trade and the pre-production of forged products. The use of a RASACUT XXL for the cutting of tubes of a wall thickness up to 15 mm and diameters up to 170 mm as well as solid bars of diameters up to 160 mm results in a cutting time reduction by up to 90 % compared to up-to-date band saws - while the quality of the cut surface is significantly improved.

For stainless steel processors, RSA is providing the saw RASACUT TC which is able to cut thin-walled tubes of a wall thickness from 0.4 mm without deforming them and protecting their surface.

For the main customers of the components suppliers to the automotive industry, RSA developed two sawing centers for specific applications. One is designed for the production of vehicle lines from 0.6 mm diameter that are deburred or chamfered on both ends and subsequently cleaned on the inside and outside with a degree of purity never reached before.

A second specialized sawing center concerns the high precision cutting, facing, chamfering, and checking of solid bars to be further processed into motor shafts.

Though there is a good domestic demand, RSA sees a market potential for these state of the art installations more likely abroad. It is evident that the East European countries move up and do no longer use lower labour costs as an argument, but also convince with quality.

According to Rainer Schmidt, the increase in orders does not result in delivery delays: "Though our delivery times are shorter than the usual delivery times in the market, we are aiming at even significantly reduced delivery times, however, this is really impossible to realize at the moment. Otherwise we are able to meet our delivery times, because we have allowed for the growth - and as a result extended the production capacities and the resources of the after-sales service."