RASACUT XS/MXS

Aktualisiert am: 16.07.2013 14:01

RASACUT XS/MXS: Two sawing centers for small tubes and large quantities

Getting fast accurately sawn tubes

As a more efficient alternative to bundle cut saws the high performance single cut saw RASACUT XS of RSA cutting systems GmbH, Schwerte, aims at large batches in the diameter range between 6 and 50 mm. An output of up to 5,000 parts per hour is achieved particularly through a fully automated processing cycle and very short ancillary times due to feed grippers working in parallel. The central clamping of the workpieces facilitates the use of small diameter saw blades even of solid-carbide and allows high cutting speeds. Small diameter saw blades improve the length accuracy of the cut pieces and significantly reduce tool costs, because small diameter saw blades are more precise and cheaper. Conclusion of RSA business manager Thomas Berg: Together with the high output extremely low cutting costs are thus achieved!

With triple cut to a flood of parts

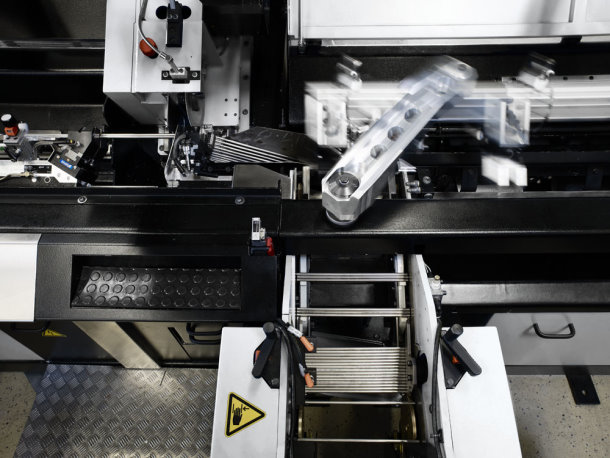

The one who wants to reduce piece costs in the tube processing even further and moreover has a particularly high demand for parts chooses the triple cut sawing center RASACUT MXS for production quantities up to 11,000 pieces/h and a diameter range of 8 up to 22 mm in triple cut and 6 up to 50 mm in single cut. The special constructional design stands for a particularly high surface quality of the sawn parts. Moreover a saw blade change in less than one minute contributes to the high output. There are variable cutting speeds possible up to 450 m/min. The extremely high output performance is also due to the reliable transfer of fixed lengths by a pick & place system and to the precise high-speed material feed that operates at speeds up to 5 m/s. Both sawing centers can be used for all applications, where small diameter tubes are to be sawn, e.g. tubes for headrests, seat frames, fuel and brake lines, refrigerators and heat exchangers. A wide range of applications is ideal for automotive parts, where high demands on accuracy, surface quality and purity can be met, even with optional follow-up processing, measuring and cleaning modules.

Everything automatically: feeding and further processing

In the context of the fully-automatic processing cycle, the raw material tubes are automatically singled and fed. As a result, personnel costs are reduced, because a worker can operate several saws. For the further processing of the tubes after cutting, the RASACUT XS / MXS just like every RSA saw can be expanded to a processing center with various optional modules. In this way, the processes sawing, deburring or facing and chamfering, length measuring, roundness checking as well as cleaning and stacking can be combined in a line. Feeding to the respective processing steps is effected automatically so that neither automatic singling machines nor a manual feeding is required.

Virtually no loss of time in smooth tube Transport

In contrast to a bundle cut saw, the single cut of the RASACUT XS increases the surface quality of the tubes. Because apparent motions in a tube bundle or layer would lead to scratches on the tube surface; moreover minimal offsets in the tube bundle are responsible for tolerance deviations. Coated tools for RASACUT XS / MXS help to protect the tube surfaces. The RASACUT XS achieves in single cut the same high output values as bundle cut saws and even more depending on the dimensional range which is partly due to the consequent reduction of ancillary times. RSA Sales Manager Dieter Bartsch specifies: The singling of the tubes from the crane bundle is carried out automatically. The random material is then fed via two special grippers achieving an acceleration of up to 40 m/s2. During the current sawing process the next tube is fed so that there is almost no loss of time when changing over to the next stock length. After all, for a tube with a diameter of 8 mm and a fixed length of 250 mm and in consideration of the output values of the RASACUT XS, more than 150 stock length changes per hour are necessary (stock length 6,000 mm), whereas other sawing machines have longer ancillary times. Saw forward feed, workpiece handling and the drive of the sawing centers RASACUT XS / MXS are carried out by servomotors and thus without hydraulics.

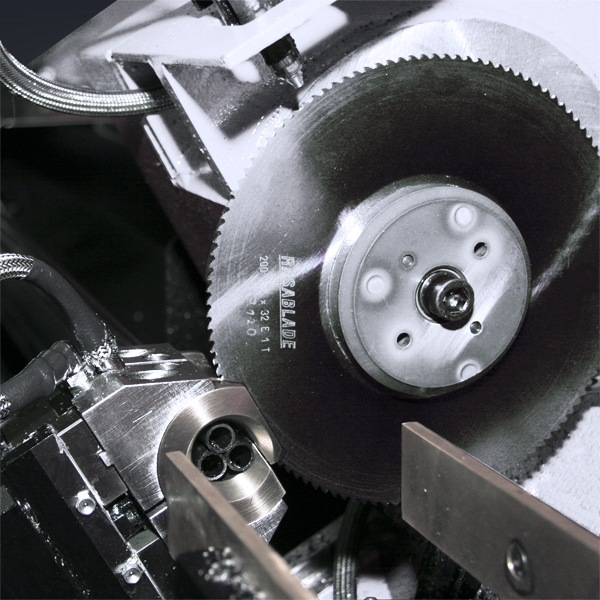

Individual sawing tools at a low Price

Sawing blade diameters are between 175 and 200 mm. Depending on the material, HSS saw blades, carbide or solid-carbide saw blades can be used. RSA specifically coordinates the teeth profiles with the properties of the workpieces to be sawn. The use of saw blades with small diameters and high speed drastically reduces the cutting time. To cover the entire workpiece spectrum with saw blades of this diameter range, the tubes are centrally clamped, not on a support.

For more information, see www.rsa.de