Production capacity of the Voortman V613 Drilling system increased!

Aktualisiert am: 06.03.2006 14:17

A few years ago Voortman introduced the V613 drilling system, this production machine is equipped with a single rotating drilling unit to drill both flanges as well as the web of steel profiles fully automatically.

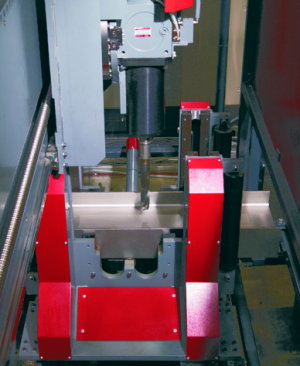

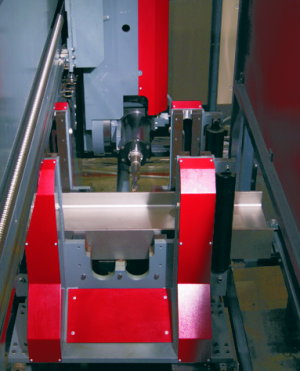

Due to the rotating drilling unit and the twin automatic tool changers this system is an extremely efficient machine to automate the prefabrication process, especially for medium sized structural steel fabricators who have to handle many different drill diameters. From the introduction in 1998 the V613 drilling system was very successful, in the last few months Voortman has redeveloped the V613 using all the la-test technical developments. The newly developed V613 drilling system is based on the existing concept whereby the most important criteria were increasing the production capacity. Therefore the machine is equipped with 2 automatic tool changers and is also constructed so that it is suitable for drilling with tipped drills.

Tool changers

Tool changers

For automatic changing of different drill diameters the machine is equipped with 2 tool changers, resulting in minimal disruption of the production process. This is due to the availability of drills for the left and right flange resulting in minimal movements of the drilling units.

Each tool changer has a magazine for 5 tools in the range of drill diameter 8 to 40 and thread tap diameter M8 to M24.

Tipped drills

Tipped drills

Besides HSS-oil-tube drills with internal coolant the machine is also suitable for drilling with tipped drills. This is made possible by the large speed range and the stable construction of the drilling system. The effective drilling time is reduced considerably by using tipped drills.

Positioning of profiles

For automatic positioning of the profiles into the drilling system the system can be fitted with a feeder truck or a positioning system with feeder rolls. The feeder truck is fitted with a material detector, which guarantees a high positioning accuracy. The positioning system with feeder rolls is integrated in the drilling system. With this extremely accurate measuring system the profiles are positioned quickly and also the machine requires less floor space.

Band sawing machine

Band sawing machine

As an option, the V613 drilling system can be combined with a Voortman mitre-cutting band sawing machine type VB600, VB750 or VB1050. These robustly built sawing machines are each equipped with an automatic mitre adjustment, hydraulic band tension and hydraulic material clamps. Because the feed is automatically adjusted to suit the profile type and size the sawing time is reduced.

Handling

Handling

For the automatic infeed and outfeed of profiles the machine can also be fitted with cross transport conveyors. These cross transport conveyors transport the profiles automatically one by one on to the infeed roller conveyor. After processing the profiles are automatically transported on to the outfeed cross transports. Depending on the quantity of buffered starting lengths the machine can work unmanned for considerable periods.